Railroad worker safety is a global concern. Railroad workers have an important role in keeping the railroads safe for passenger and freight trains through rail system inspections, maintenance, and repairs on the trackway. While performing these duties to help provide safe railroad tracks for the industry, the track workers themselves are faced with safety risks unique to their line of work. Traditional worker protections rely mainly on other workers providing a notification of an approaching train which leads to a wide array of potentially dangerous situations caused by human error.

Common safety risks with traditional railroad worker protection standard operating procedures include:

- Relying on a lookout or watchman provides a single point of failure

- Worker complacency, boredom, inattention, and fatigue

- Workers being given more responsibilities with less time to complete tasks

- No advanced warning to train operators of workers ahead

- No advanced warning to track workers of an approaching train

- Increased equipment/convoy movements on tracks

Protran Technology offers several Railway Worker Protection Systems utilizing innovative technology to protect both railway workers and railroad equipment, in an effort to mitigate various types of dangerous scenarios found on the railroad.

Typical hazard scenarios working on the railroad include the following:

Fixed Work Zones

When track workers are engaged in work activities on the railroad in fixed work zones, they must enter the track area and rely on themselves and a variety rules, procedures, and other personnel to protect them from moving traffic. Generally, any fixed work zone is defined by a set of pre-approved “limits” with starting/ending locations. For trains or equipment to enter these active work areas, they must be given authorization before proceeding into the pre-determined work area. There are times when the work limits are miscommunicated, locations are not clearly defined, and those who are flagging or moving equipment become distracted and fail to provide ample warning to track workers.

Moving Work Zones

When track workers are engaged in work activities on the railroad which require them to continuously be moving (i.e. inspections, tree/vegetation cutting, etc.), they must enter the track area and are exposed to hazards unique to this type of access. Generally, this type of activity relies on “notification” of the workers locations to trains from controllers, and/or the roadway worker is required to use visual train detection to move to a place of safety when they observe a train approaching. Unfortunately, these types of moving work zones can place railway workers in places where train operators are not aware of their current location due to poor communication with controllers and at times the physical characteristics of the railroad do not allow the workers to see the trains with enough time to clear without urgent movement. Additionally, due to a variety of physical characteristics of the railroad, workers can find themselves in areas where there is no safe clearing location.

Equipment Movement – Collision Avoidance

Track work requires the use of multiple pieces of heavy maintenance equipment to maintain the track structure. In a typical work area, there can be many activities which are run concurrently or in a sequential manner. During these activities, equipment is constantly moving, operators are usually focused on their work (i.e. tamping, ballast regulating, grinding, etc.) and workers can be placed in danger of being struck by this equipment. Even when railway workers are not involved, slow speed collisions between maintenance equipment can injure operators and damage costly equipment.

Protran Technology Roadway Worker Protection (RWP) Systems are secondary warning systems that provide advanced warning of approaching trains to wayside workers, as well as warnings to the train operators of workers present on the tracks. The Protran RWP systems are range based systems that use GPS location along with proprietary ranging RF technology to give the most accurate alerts possible.

Protran Technology Portable Protracker

Railway Worker Protection System

The Portable Protracker System is a portable train detection system used to alert track workers of an approaching train. This system is used as a secondary warning system to add an extra layer of safety to an agency’s existing rules and procedures. The portable system is best used in “fixed” work zones where a defined work area has been established. This system provides an alert to the track worker only and does not communicate worker location or notify the train/ vehicle operator of workers ahead.

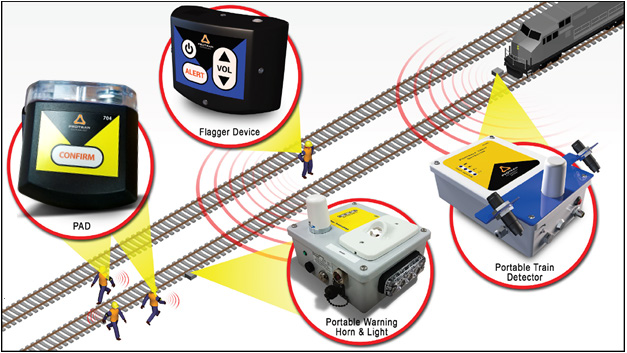

The Portable Protracker System utilizes train detectors which are positioned ahead of the work zone so that if primary safety protections are violated, the track workers will still be warned of the approaching train with both visual and audible alarms via the Protran Portable Warning Horn & Light (PWH&L) work crew device, Flagger Device used by the watchman/lookout, and track worker Personal Alert and Devices (PAD) when a train or other on-track vehicle is approaching the work area.

The Portable Protracker train detection system is compiled of four main components:

- Portable Train Detector

- Portable Warning Horn & Light + Repeater

- Personal Alert Devices

- Flagger Device

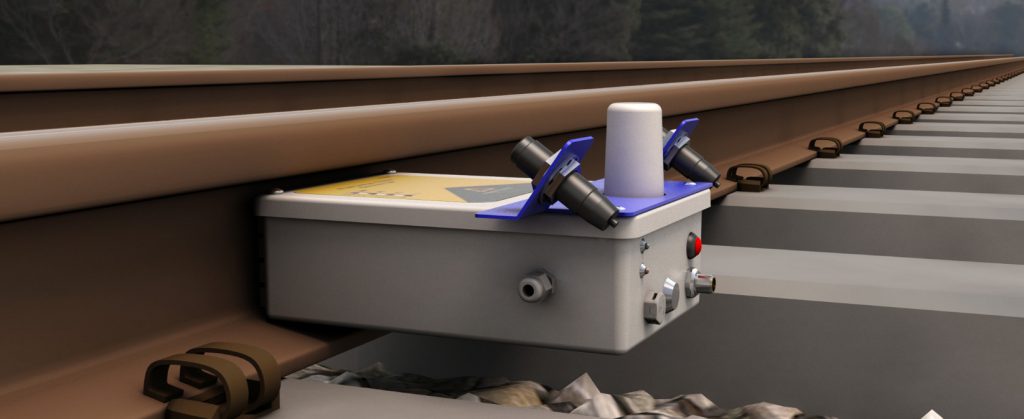

The Portable Train Detector is magnetically attached to the web of the rail and is placed ahead of the work zone where a train will be approaching from or can be placed at both ends of the work zone for two-way traffic protection. The Portable Protracker is equipped with two sensors that will detect when a train passes by. When the train passes over the device, the Portable Protracker will activate and transmit an alert signal. This signal will activate any

Portable Warning Horn & Light (PWHL), Flagger Device, and Personal Alert Device (PAD) that is within range.

The Portable Warning Horn & Light (PWH&L) is placed in the beginning of the work zone where it can be seen and heard by the work crew. The Portable Warning Horn & Light device gives an audible and visual alarm to the workers when a train or on track vehicle is approaching. This device can be activated by a Portable Protracker rail-mounted unit, Ranging Protracker train-mounted unit, or manually using the Flagger Device. In long work zones or areas of high speed trains, multiple Portable Warning Horn & Light devices can be spread out along the work zone to repeat the warning signal from either the Train Mounted Unit, Portable Protracker Train Detector, or Flagger Unit.

The Flagger and Personal Alert Device (PAD) is worn by the track worker to provide an audible and visual advanced warning to the worker of the train/vehicle approaching the work zone. The PAD will receive an advanced audible and visual warning of the train approaching providing the worker using the PAD ample time to clear the tracks safely so the train can proceed. The Flagger Device is utilized by the person acting as the Flagger / Watchman / Lookout or the Employee in Charge. This device functions the same as the Personal Alert Device worn by the track workers but has one additional feature: an ALERT button. The ALERT button allows the Flagger / Watchman to be able to manually alert all the PWH&L and PADs in the work zone of an approaching train/vehicle or any other emergency that would require a warning notification to the crew.

Protran Technology Ranging Protracker

Railway Worker Protection System

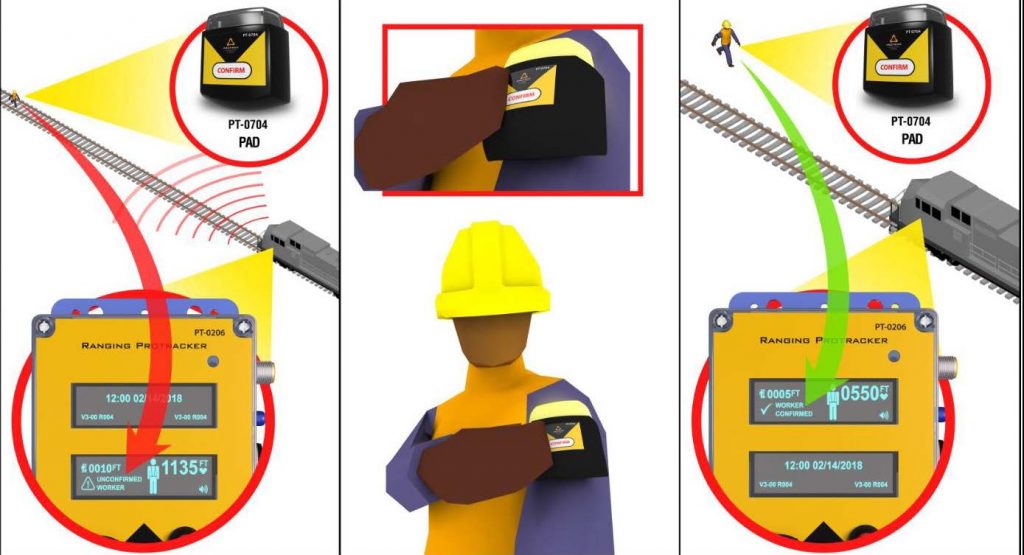

Utilizing Protran Technology’s Ranging Protracker System, both personnel and train fleet are outfitted with Protran equipment so that the worker will receive an alarm when a train is approaching, and the train operator receives an alarm that they are approaching workers ahead on the tracks. This sophisticated technology includes a user-friendly display screen that provides the train operator the distance they are away from a worker and allows the worker to communicate with the train that they are in a position of safety. When combined with appropriate operating rules these systems virtually eliminate all close calls.

The Ranging Protracker safety system is compiled of four main components:

- Ranging Protracker Train Mounted Device

- Portable Warning Horn & Light +Repeater

- Personal Alert Devices

- Flagger Device

The Protran Technology Ranging Protracker train device is designed to be mounted in the cab of a train utilizing the custom Protracker Antenna Kit. The train operator will be audibly and visually alerted of personnel near the train tracks who are wearing the Protracker Personal Alert Device (PAD). These devices enhance an agency’s existing safety procedures utilizing GPS and ranging radio technology with multiple interfaces such as Ethernet, RS232, and RS485.

The Ranging Protracker system will detect workers on the tracks who are wearing the Personal Alert Device (PAD) device and provide ample time for workers to clear to a place of safety. The cab-mounted device provides the train operator with a large screen display in which they receive distance to worker information and acknowledgement that a worker has received the train approach warning. This technology requires the roadway worker to “confirm” they are clear of the train and indicate to the train operator that they may proceed. If the worker does not indicate they are clear, the operator can stop at an agency pre-determined distance. This system provides workers with ample time to clear to a place of safety along with additional features such as event data logging, configurable alarm parameters: distance-based alarms or time-based alarms, and discernible “second train” alarms.

Ranging Protracker Railway Worker

Protection System

The Ranging Protracker System provides data logging of all alert and detection data to enhance an agency’s data collection capabilities and can be used to validate existing procedures and assist in incident investigations (near misses, accidents, etc).

One of the many benefits to the Ranging Protracker is the ease of use. Daily set-up is virtually automatic as the system turns on when the train is powered up and the workers wearing PADs are always protected. Initial installation for this system is very simple and can be integrated into any existing fleet or new build of transit vehicles. These units are low maintenance and easy to use; training for both the operator and the track worker is quick and easy to fully understand the functionality.

Protran Technology Collision Avoidance System

Track maintenance equipment can be outfitted with Protran Technology’s Collision Avoidance System (CAS) that can work to eliminate collisions between equipment, collisions with workers, and provide notifications of work zone limits. The Collision Avoidance System is a vehicle-mounted unit equipped with a high-resolution display that emits a visual and audible alarm when approaching other vehicles, workers, and work zone limit devices. The CAS utilizes Protran Technology’s advanced ranging radio technology to set custom distances and alert parameters for all the equipment in the work gang. When maintenance vehicles are outfitted with CAS technology, it allows operators, who may be distracted by the work they are doing, to receive alarms when another piece of equipment gets too close to the machine they’re operating, whether it is from their movement or the other equipment’s movement. By keeping the operator’s attention, the system prevents costly accidents and injuries. The CAS can be programmed to allow for multiple warning alarms and emergency alerts in both Work Mode and Travel Mode. The Protran Technology Collision Avoidance System is simple to learn, easy to configure, starts up automatically when the track maintenance vehicle is powered on, and can stop collisions from happening.

Railroad agencies desire safety systems that offer reliable advanced warning to the track workers of a train or on-track-equipment approaching the work zone. Providing the track workers with an advanced warning system as a secondary measure to protect their well-being so they can perform their job duties without injury is of the utmost importance. Utilizing a system from an experienced safety solutions technology company is the key to successful implementation.

Protran Technology offers reliable Railway Worker Protection systems that are easy to implement from installation to everyday use with low maintenance that easily fit into agencies standard operating procedures. The RWP systems provide useful tools that provide advanced warning to operators and track workers to help mitigate accidents. Implementing a system with flexibility to be configured to meet the agencies unique operating environment is important and necessary to be effective.

For more information, visit www.ProtranTechnology.com

Share on: