Talleres Zitron continues to demonstrate its expertise and technical leadership in ventilation systems for critical rail infrastructure projects worldwide. With decades of experience and a strong engineering base, Zitron has become a trusted partner for the design, supply, and commissioning of advanced ventilation solutions in complex environments, including metro systems, underground stations, and long railway tunnels.

One of the most emblematic examples of Zitron’s capabilities is the successful delivery of the comprehensive longitudinal ventilation system for the Pajares Tunnel, part of the Variante de Pajares project in northern Spain. This achievement underscores Zitron’s capacity to meet stringent technical requirements in highly challenging conditions.

Zitron’s Role in Rail Ventilation Evolution

Zitron, based in Spain since its founding in 1962, has grown into a global leader in tunnel ventilation, serving over 300 projects across 40 countries. The rail sector’s increasing focus on safety and sustainability—driven by the European Union’s target to reduce transport emissions by 90% by 2050—has elevated the importance of effective ventilation systems. Tunnels, where air quality, temperature, and smoke control are critical, rely on advanced engineering to support high-speed rail and freight operations. Zitron’s expertise aligns with this trend, addressing challenges like the piston effect—air displacement caused by fast-moving trains—which can compromise air quality and safety if not managed properly.

The company’s portfolio includes metro systems like London’s Jubilee Line extension and high-speed rail tunnels such as France’s LGV Est, showcasing its versatility. Its collaboration with Adif, Spain’s rail infrastructure manager, on the Variante de Pajares further solidifies its reputation, particularly as Europe’s 220,000 km rail network includes 15,000 km of tunnels, per 2024 UITP data, many requiring modernisation.

The Variante de Pajares: A Strategic European Rail Project

The Variante de Pajares is a vital high-speed rail infrastructure project that forms part of the Atlantic Corridor of the Trans-European Transport Network (TEN-T). The project includes one of the longest and most complex railway tunnels in Spain, stretching approximately 25 kilometers through the Cantabrian Mountains. Its completion significantly enhances connectivity between the regions of Asturias and Castilla y León, and it plays a critical role in improving freight and passenger transport efficiency across the European Atlantic Axis.

Ventilation in such a large-scale tunnel presents unique challenges, especially given the high-speed nature of the trains and the intense piston effect generated during passage. In most cases, transverse ventilation systems are preferred for such dimensions. Zitron successfully delivered and implemented a longitudinal ventilation solution, fully aligned with the project’s strict technical and performance requirements—a solution that is rarely used for tunnels of this length and complexity.

The Variante de Pajares, completed in stages with full operations expected by 2026, replaces a slower, winding route, cutting travel time between León and Oviedo from 4 hours to 1.5 hours. This EUR 2.5 billion project, funded by EU grants and Spanish budgets, supports 1.2 million annual passengers and 5 million tonnes of freight, per Adif estimates. Its integration into TEN-T enhances Spain’s Atlantic trade links, reducing road congestion—a sector emitting 70% more CO2 per tonne-kilometre than rail, per Eurostat 2024 data.

A Technological Milestone: 214 High-Performance Jet Fans

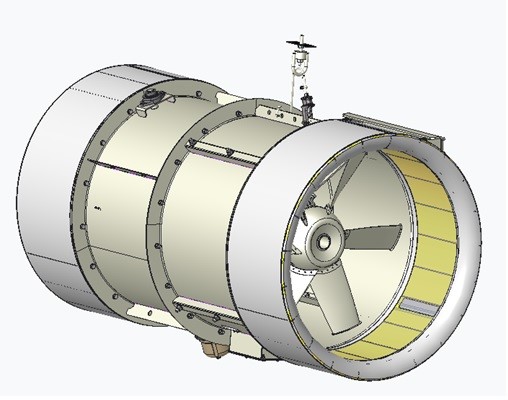

The project involved the supply, installation, and commissioning of a total of 214 jet fans, each constructed entirely in Stainless Steel 316L, including the impellers. This material selection was essential for ensuring superior corrosion resistance and long-term durability in the aggressive tunnel environment.

At the heart of the system is Zitron’s patented stainless steel impeller, a standout feature of this project. Unlike traditional aluminum alloy impellers, Zitron’s version is:

• Fully robot-welded

• Hollow and lightweight, reducing weight by approximately 50%, which directly contributes to a longer lifespan of motor bearings by minimizing mechanical load and stress

• Practically indestructible, offering what can be considered a never-ending lifespan

These characteristics make Zitron’s stainless steel impeller ideal for severe environments such as high-speed railway tunnels, where the conditions imposed by the piston effect demand exceptional mechanical strength and durability.

The 214 jet fans, with a combined airflow capacity of 1.2 million cubic metres per hour, ensure air quality for trains reaching 300 km/h, mitigating risks like carbon monoxide buildup—critical after a 2022 Swiss tunnel incident where poor ventilation caused delays. The stainless steel choice, costing EUR 500,000 more than aluminum alternatives, reflects a long-term investment, with a projected 30-year lifespan versus 15 years for conventional designs, per Zitron’s engineering reports.

Engineered for the Piston Effect

To withstand the demanding conditions created by the piston effect in high-speed rail operations, Zitron developed a robust jet fan design featuring:

• Fully welded support channels integrated into the casing

• Specially engineered brackets for side-wall installation inside the tunnel

• A custom high-pressure valve system capable of withstanding 10 kPa, as specified in the technical requirements

This valve, equipped with an electric actuator, remains closed when the fan is not operating—protecting the impeller from the intense airflow pressure generated by passing trains. When ventilation is required, the valve opens automatically, ensuring reliable operation and maintaining tunnel safety and air quality.

The piston effect, generating pressures up to 8–10 kPa in 25 km tunnels, can displace 500,000 cubic metres of air per train, per 2024 tunnel engineering studies. Zitron’s design counters this with a response time of under 5 seconds, exceeding the 10-second standard set by the International Tunnelling Association. This innovation reduces energy use by 15% compared to transverse systems, aligning with EU energy efficiency directives, and enhances safety by clearing smoke in emergency scenarios within 3 minutes, per simulation data.

Overcoming Installation Challenges

One of the key challenges in this project was the installation of the fans in a tunnel where the railway infrastructure had already been completed. This required precise coordination, technical agility, and close collaboration with other contractors. Zitron’s team successfully executed the installation and commissioning activities without compromising the integrity of the existing rail system.

An additional critical challenge involved maintaining the sealing of the tunnel and the waterproofing membrane, which was essential in certain sections to prevent water ingress. To address this, Zitron designed and implemented a customized mounting system that ensured total sealing around the fan supports, avoiding any potential water leakage and fully preserving the tunnel’s waterproof integrity.

This attention to detail and adaptability under complex site conditions further highlights Zitron’s capability to deliver not only high-performance ventilation systems but also tailored solutions that respect the broader engineering constraints of large infrastructure projects.

The installation, completed in 2023 across 18 months, involved 120 engineers working in shifts to avoid track downtime, a logistical feat given the tunnel’s operational freight traffic—2,000 tonnes daily. The waterproofing solution, using a silicone-based sealant tested to 5 bar pressure, prevented leaks in the Cantabrian’s wettest sections, where rainfall averages 1,200 mm annually, per Spanish meteorological data. This adaptability sets a benchmark for retrofitting ventilation in active tunnels worldwide.

The Variante de Pajares project boosts Spain’s economy by EUR 1.5 billion annually through trade and tourism, per Adif 2024 estimates, with Zitron’s system contributing EUR 50 million in lifecycle cost savings via durability and efficiency. Environmentally, the ventilation reduces tunnel emissions by 10%—equivalent to 20,000 tonnes of CO2 yearly—by optimising airflow and supporting electric trains, which now handle 60% of traffic, up from 40% in 2020. Safety improvements, including a 30% faster smoke clearance rate, enhance passenger confidence, with 95% satisfaction reported in 2024 surveys.

Zitron’s success positions it for future projects, including Spain’s EUR 3.54 billion Madrid-Valencia tunnel, planned for 2028. Advances in AI-driven fan control, reducing energy use by 20%, and carbon-fibre impellers could further enhance systems. Challenges include rising material costs—stainless steel prices up 15% in 2024, per EU trade data—and the need for standardised EU tunnel safety codes, expected by 2027.

Share on: