Digital train functions provide rail freight transport with a much-needed performance boost. In-depth monitoring and automation of previously time-consuming, manual processes reduce costs while increasing the efficiency, availability and safety of freight trains. The technology provided by PJM is available and is already being used by European rail logistics companies and railroad undertakings.

The technical concept and development of the extensive overall system focused on general requirements such as a powerful power supply, compatibility with other systems and all wagon types, simple installation and freedom from maintenance, as well as real-time monitoring functions that provide direct benefits. In addition, the investment costs must be manageable and the amortization period short.

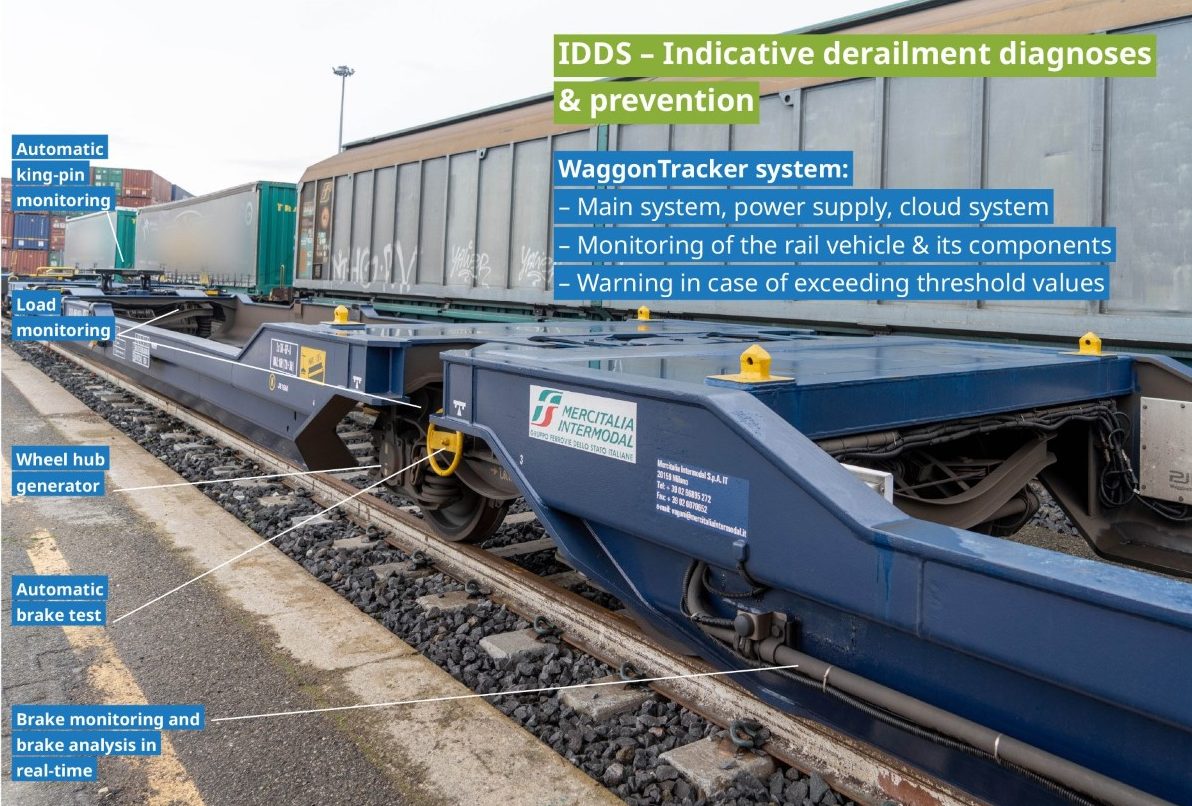

PJM’s smart train technology integrates a suite of advanced features designed to optimize freight operations:

• Automated brake test via tablet: Streamlines a critical safety procedure and automatizes the operational process of checking the brakes.

• Automated load weight monitoring: Ensures compliance with the permitted load capacity and optimizes load distribution.

• Brake monitoring and brake system analysis in real-time: Provides immediate insights into brake performance and is an important component in predictive maintenance.

• Kingpin monitoring in real-time: Crucial for intermodal transport safety.

• IDDS Derailment Diagnoses: Early detection of derailments and direct communication in real-time to the train driver.

• Monitoring of running characteristics: Includes, among others, tracking wagon performance as well as detecting flat spots and assessing running dynamics. This information also allows conclusions to be drawn about infrastructure damage and enables predictive maintenance.

The effectiveness of PJM’s digital overall system stems from several core pillars:

The effectiveness of PJM’s digital overall system stems from several core pillars:

• Autonomous and powerful power supply: Currently, the preferred solution for self-sufficient power for demanding functions is the wheel hub generator. The power supply is designed to be sufficiently powerful, even for additional, customer-specific applications or future applications.

• Comprehensive monitoring functionality: Relevant freight wagon data is recorded, processed, and transmitted to a web service in real-time. This data is categorized into:

– Advanced data (statt basic data): Includes mileage, direction of travel, current position, last message, last movement, and historical data.

– Sensor data: Encompasses loading status, running behavior, axle bearing temperature, brake system status, consumed energy status, derailment status, load weight, shock monitoring, trestle status, ambient temperature, and more. These data facilitate predictive maintenance. Furthermore, they provide relevant information on the braking behavior and use of the brakes (e.g. when brakes are applied to much).

• Advanced safety electronics and in-train communication: The functional safe acquisition of measurement data, combined with a secure connection to a central control unit, forms the foundation for automating operational processes. The in-train communication system utilizes a long-range radio system engineered for maximum availability, ensuring an encrypted, secure connection and direct communication with the train driver.

• Scalability: The overall digital system is highly scalable, accommodating customized and future applications. Its modularity allows for the integration of any number of sensors, such as those for axle bearing temperature monitoring.

• DAC compatibility: The WaggonTracker system currently incorporates a wagon on-board control unit. As a backbone on the wagon and in the train set, it provides digital train functions and is also designed to be compatible with future applications. When the DAC will be rolled out, the train functions will be extended by automated coupling and train power supply and communication lines will be used.

• Full system compatibility: The PJM system is also compatible with other customized applications and remains independent of other technologies or wagon equipment.

• Universal wagon type compatibility: The WaggonTracker is suitable for all wagon types and can be installed ex works on new wagons or seamlessly integrated into existing wagon fleets. Its ease of installation, robustness, and largely maintenance-free nature make upgrading existing wagons a sound economic decision due to its durability and immediate benefits.

• Simple integration: Integrating the WaggonTracker system into a wagon fleet is straightforward. The upgrade process is flexible: PJM can install the system, or wagons can be rented fully equipped through their partners VTG, TRANSWAGGON, or GATX. Furthermore, Europe’s largest wagon manufacturer, Tatravagónka, is already supplying wagons with automatic brake testing and all other digital train functions directly from the factory.

• Approved & available technology: The WaggonTracker system is not just a concept; it is an approved technology already in use at renowned railway companies and is now readily available.

Rail transport companies have to face big challenges: cost pressure due to several factors (infrastructure, personnel, etc.), a shortage of skilled workers due to demographic trends, long downtimes for various reasons (regulatory requirements, lengthy train preparation, manual work, etc.) and, at the same time, great responsibility for the safety of freight trains must be managed in the best possible way. With the right technical equipment, efficient, available, environmentally friendly and safe rail transportation can be put on track.

Let’s talk about digital rail freight!

Transport Logistic 2025, Munich

PJM booth: B6.116

Railway Forum Berlin

Share on: