Railways may be safer than they were a century ago, but despite the technology available to us now, the pace of development has slowed.

Last year’s EU Report on Railway Safety and Inoperability in the EU found that whilst railway operators have succeeded in reducing staff casualties, there has been an alarming increase in employee fatalities, with 24 de

aths being reported in 2022. It would appear then, that although there have been some improvements in the interoperability of EU railway systems, this progress is uneven across certain areas.

UK-based depot safety specialist, Zonegreen, is calling for more to be done to improve conditions in maintenance facilities and wants to see operators be more proactive.

As part of the Sentric Safety Group, Zonegreen is the world leader in depot protection solutions, and is one of the latest companies to sign the European Railway Safety Culture Declaration, joining more than 400 organisations committed to improving the region’s safety culture.

Christian Fletcher, Zonegreen’s head of engineering, said: “Although the European declaration demonstrates a willingness to improve rail safety, progress so far is slow and inconsistent. The installation of train protection systems is widely considered one of the most effective ways to make a difference, yet several still in use within the EU are obsolete and have low reliability levels.”

Safety culture is defined as the interaction between the requirements of a safety management system, how people make sense of them, and what they actually do. The organisations that have signed the EU declaration are committed to taking the necessary steps to manage the risks faced by rail workers, including those related to the limits of human reliability.

Christian added: “Regardless of training and experience, individuals working in dangerous environments, such as rail depots, can become the victim of unexpected events or the mistakes of others. Investing in the latest technology helps rail depots develop positive attitudes to safety and increase the efficiency of their operations.”

Mitigating human error

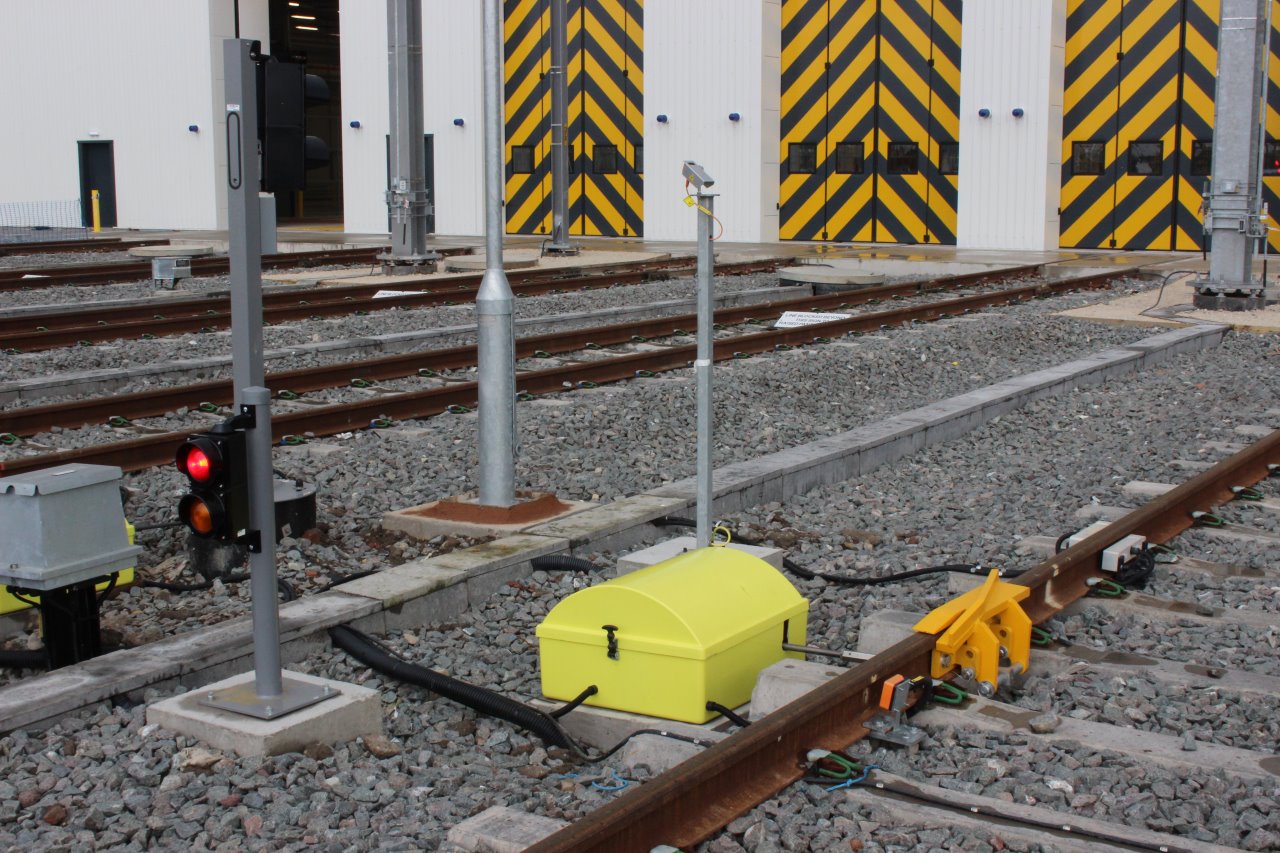

The Zonegreen Depot Personnel Protection System (DPPS) aligns perfectly with the principles of the Safety Culture Declaration, which encourages organisations to promote safe behaviour and provide an appropriate environment for work to be undertaken, free from harm.

DPPS automates safety procedures, mitigating the risk of human error associated with manual protection. This allows the efficient control of vehicles in a maintenance environment and significantly reduces the hazards faced by staff.

The system is operated by contactless RFID cards that can be programmed with various levels of authorisation. When beginning work in an area of risk, employees log on to road end panels that prevent derailers from being lowered, stopping vehicles from entering the occupied area. This creates a ‘safe zone’ in which the individuals can carry out tasks without concern for their safety or interruption.

Access permission must be given to a train by a supervisor, via the controlling road end panel, which is positioned at a convenient location within the maintenance building. This is usually next to the depot doors, giving the operator a clear view of incoming and outgoing vehicles. Only after the derailer has been lowered will the shunt signal change to ‘proceed.’ Audible and visual warnings are then activated to alert staff to imminent vehicle movement.

The Zonegreen DPPS system is one of the safest on the market, boasting independent certification to prove its compliance with both the hardware and software integrity requirements of SIL 2 – a reliability assessment of the relative risk reduction provided by a safety system. It is also the most thoroughly tested and proven in use, offering a low-risk option to depots looking to improve their working environment.

In addition, Zonegreen’s third generation DPPS RFID panel has been independently certified by Eurofins to be compliant with both the EN 300 330-V2.1.1 radio emissions standard and railway standard EN50128/50129.

Christian continued: “Mainte-nance facilities as far afield as Australia are already protected by our tried and tested solutions and we believe they could be widely beneficial to those who have shown a willingness in the Safety Culture Declaration to reduce European railway worker casualties and fatalities.”

The future of interlocking

Zonegreen also supplies a range of interlocking solutions that protect both personnel and equipment in rail maintenance facilities. These vital systems prevent unauthorised train movements or access to high-risk areas and ensure that safety standards are upheld.

Both electronic and trapped key interlocking solutions are available in modular systems that can be modified and updated as a depot grows.

Traditional trapped key interlocking requires the transfer of a physical key between equipment. In complex environments, such as large depots, the distance between locks can limit the speed of operations. Electronic interlocking, however, substitutes these physical keys with a programmable logic controller that can be connected to any depot equipment, vastly increasing the rate at which restricted areas can be accessed, without compromising safety.

HMI monitors are used to show operators the status of all gates, whilst hardwired sensors send signals back to the monitors, so no one has to walk miles. This means safety gates will only open when equipment is stowed correctly, making it safe to do so.

Expanding across Europe

The European Railway Safety Culture Declaration notes: “In an operational railway environment, individuals, despite their training and expertise, may be faced with situations where the limits of human reality, combined with unpredictable influences, may lead to an undesirable outcome.” Its goal is for the EU to be at the forefront of railway safety, and it identifies infrastructure managers as having a key role to play.

Rail is the only mode of transport for which targets have been prescribed by EU legislation, and as a world leader in depot protection, Zonegreen rail safety solutions can help the sector meet these goals. It utilises the very latest technology to keep driving improvements in personnel safety and its team of specialist engineers is constantly innovating and developing its product range.

DPPS already protects thousands of rail workers across the UK, Australia, New Zealand and the United Arab Emirates, and together with colleagues at the Sentric Safety Group, Zonegreen is rapidly cementing its reputation across Europe.

Gemma Houghton, the Sentric Safety Group’s head of rail, added: “Zonegreen is an excellent ambassador for our group, demonstrating how technology can be used to automate safety procedures, reducing the risks faced by rail maintenance staff. We are very proud of the progress being made, as well as the hard work that is fuelling its growth.”

For more information about Zonegreen’s suite of rail depot protection solutions, telephone +44 (114) 230 0822, visit www.zonegreen.com or follow them on LinkedIn: Zonegreen Ltd.

Share on: